Healthcare, Industry, Offices, Farms, Public Spaces, Households, Transportation, Warehouses and many more...

Why Hydrofogg ?

Certified technological equipment for the production of aerosol dry fog, designed for whole-space disinfection without surface wetting that will allow you to achieve optimal results in all aspects of cleaning and disinfection.

• Creates a fine aerosol dry fog that can effectively penetrate spaces, destroy bacteria, viruses and molds, while simultaneously humidifying the air and removing dust.

• The technology of droplet dispersion penetrates to all places at the point of contact with air.

• Does not damage sensitive equipment and technology, samples, paper documents, food or plants in the room.

Hydrofogg is designed with ease of use, performance and safety in mind.

• Its advanced technology enables fast and even dispersion of dry fog, while minimizing the consumption of disinfectants and leaving no wet surfaces.

• The device is connected to the appropriate source of electricity and water and the required parameters are set.

• Equipped with certified nozzles that are controlled by software via a smartphone or manually.

• Silent and compact system, the installation of which does not require a lot of space.

• Ideal for use in various environments such as hospitals, laboratories, offices, warehouses, farms, shops and many others.

More than 270 bacteriological, virological, and toxicological tests and studies confirm the convincing effectiveness of the disinfectant in combination with the certified Detectair Hydrofogg system

Bacteries:

Acinetobacter iwoffii • Aeromonas salmonicida • Agrobacterium radiobacter • Anthrax (Bacillus anthracis) • Bacillus cereus • Bacillus licheniformis • Bacillus mesenterious • Bacillus subtilis • Bacillus sp. marine • Bacteria cinerea • Bacteria erwinia • Burkholderia cepacia • Camphylobacter jejuni • Colera (V. cholerae) • Chryseomonas luteola • Clostridium novyi • Clostridium perfringens • Clostridium sporogenes • Coagulase +ve staphylococci • Comomonas acidovorans • Enterobacter aerogenes • Enterococcus feacium • Enterococcus faecalis • Enterococcus hirae • Erwinia carotovora • Eschericia coli • Flagellata apochromatica • Flavobacter Cytophaga • Flavobacterium indologenes • Galionella sp. • Klebsiella oxytoca • Klebsiella pneumoniae • Lactobacillus brevis • Lactobacillus lindneri • Lactobacillus plantarum • Lactobacillus sp. • Lactobacillus wild type • Legionella pneumophila • Leuconostoc mesenteroides • Listeria monocytogenes • Micrococcus luteus • Micrococii pyogenes aureus • Micrococcus roseus • Micrococcus candidus • Mycobacterium spez. • Neumaniella sp. • Naeglaria fowleri • Neisseria meningitidis • Ochrobactrum anthorpi • Pasteurella pedicoccus damnosus • Pedicoccus sp. • Pestis (Y. pestis) • Proteus mirabilis • Proteus vulgaris • Pseudomonas aeruginosa • Pseudomonas alcaligenes • Pseudomonas chlororaphis • Pseudomonas fluorescens • Pseudomonas spec. • Pseudomonas syringae pv. Tomato • Ralstonia picketti • Salmonella enteritidis • Salmonella paratyphi • Salmonella sp. • Salmonella typhimurium • Salmonella typhi • Salmonella typhosa • Sarcina lutea • Staphylococcus agalactiae • Staphylococcus albus • Staphylococcus aureus • Staphylococcus feacium • Staphylococcus marcescens • Stephanodiscus hantzschii • Streptococcus faecalis • Sreptococcus lactis • Streptococcus pyogenes • Tuberculosis (Mycobacterium tuberculosis, resistant strain H37 Rv) • Tuberculosis (Mycobacterium tuberculosis, wild-type strain) • Xanthomonas campestris • Zooglea sp.

Molds:

Absida corymbifera • Alternaria alternata • Aspergillus niger • Aspergillus niger spores • Aspergillus fumigatus • Botrycis cinerea • Candida albicans • Cladosporium cladosporoides • Epicoccum • Helminthosporium • Chroomonas norstedtii • Fusarium • Fusarium spp. • Microsporum gypseum • Mucor • Penicillium • Penicillium digitatum • Penicillium roqueforti • Penicillium verrucosum • Pichia membranaefaciens • Rhizopus • Sacharomyces cervisiae • Sacharomyces uvarum • Sacharomyces cereivisia var. uvarum ssp. carlsbergensis • Stemphylium • Trichophyton mentagrophytes.

Viruses:

Coronavirus - COVID-19 • Hepatitis B • Hepatitis C surrogate (BVDV) • Herpes simplex type 1 • HIV-1 • Influenza A virus • Influenza A, H5N1 • Influenza A, HS, H7 and H9 • Newcastle Disease virus • Orthopoxvirus vaccinia • Papovavirus SV- 40 • Paramyxo virus • Poliovirus 1 • Pseudorabies virus. • Trophozoite protozoa inl. Amoebae • Vaccina virus • V. parahaemolytis.

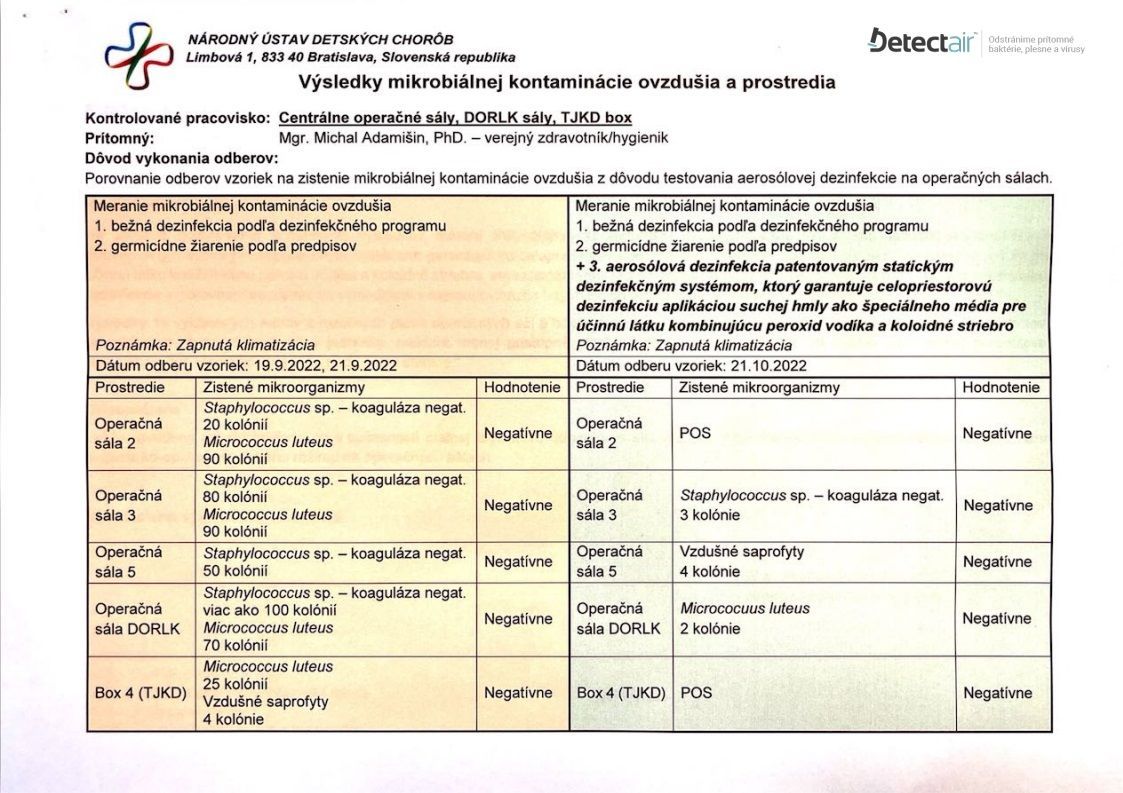

Project National Institute of Children's Diseases - Bratislava Kramáre, Slovakia

Under the strict supervision of the Chief Hygienist of the Slovak Republic, tests were conducted as part of the technology implementation, which confirmed that the technology for generating aerosol dry mist Detectair Hydrofogg in combination with the disinfectant Sanosil created significantly lower values up to sterility of the air after application compared to the results found in measuring the air in the same spaces, at the same time and place.

Based on the results obtained, the technology was subsequently implemented in 6 operating rooms and preparations are currently underway for another 8 operating rooms.

Results from the Chief Hygienist at the National Institute of Children's Diseases

Standard disinfection mode:

1. normal disinfection according to the disinfection program

2. germicidal radiation (UV lamps) according to the regulations

Staphylococcus sp., Micrococcus luteus, Aerial saprophytogheter...

A total of more than 500 colonies detected after standard disinfection mode in five operating rooms.

Standard disinfection mode + Hydrofogg:

A total of less than 10 colonies captured after added usage of Hydrofogg system in the same five operating rooms.

After consulting the results, the high efficiency of the Hydrofogg technology is visible.

Evaluation of results

Evaluation of the results:

Based on the observation and the results of measurements of microbial contamination of the air, which when using aerosol disinfection with a patented static disinfection system guaranteeing whole-space disinfection by applying dry fog as a special medium for an active substance combining hydrogen peroxide and colloidal silver, we recorded an order of magnitude lower values and air sterility after application of the mentioned disinfection in comparison with the results found in the air measurement in the same premises, at the same time and place of measurement.

The results of 19 swabs performed from various surfaces of the operating rooms and the box (e.g. anesthesiological table, touch surfaces of some devices, ventilation openings, air conditioning units, some less accessible areas and other areas) after applying the aforementioned aerosol disinfections were identified as "soils remained sterile."

Recommendation:

I recommend the above-mentioned type of disinfection under the currently valid legislation as a supplement to the above-standard provision of proper hygienic-epidemiological regime in operating rooms.

Poultry farm AGRO Slovakia

Welcome to AGRO Slovakia, where our hydraulic system Hydrofogg has been successfully implemented. With a space measuring 1000 m2, this particular installation features two lines of pipes.

Firstly, we have integrated a dedicated line for disinfection, ensuring optimal hygiene standards throughout the facility. This guarantees a healthier and safer environment for both poultry and staff. Secondly, we have incorporated a separate line specifically designed for humidification and cooling. By maintaining optimal humidity levels and effectively reducing temperatures, we create an ideal climate for poultry growth and welfare.

The Hydrofogg system offers a wide range of benefits and advantages specifically tailored for poultry farms. By producing a fine aerosol dry fog, it effectively penetrates all areas, eradicating bacteria, viruses and molds. Additionally, our system excels in humidifying the air, promoting optimal conditions for poultry growth and productivity. By eliminating dust particles, we minimize respiratory issues and create a more comfortable environment.

It guarantees optimal conditions for poultry growth while maintaining high standards of hygiene. The intelligent design and certification of the Hydrofogg system make it a versatile and reliable solution for improved poultry farm conditions.