Dry Fog Technology

- The AGROfogg® system is a static disinfection and humidification device that utilizes dry mist technology to achieve maximum air and surface cleanliness in food production and storage.

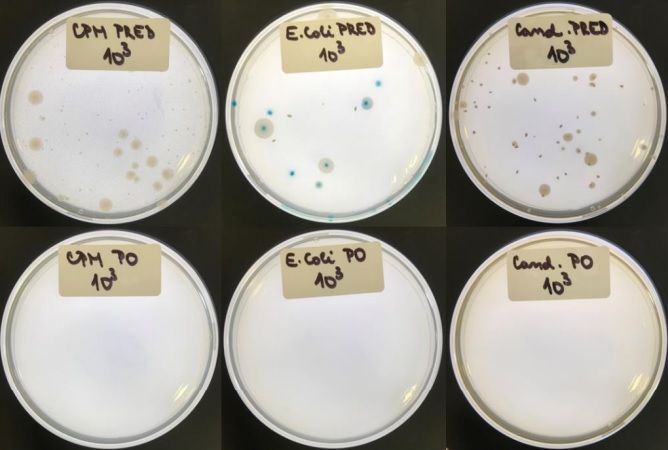

- Our system is an ideal partner for large and medium-sized food manufacturers as it effectively and demonstrably destroys pathogens such as Escherichia coli, Candida albicans, Enterococcus faecalis, Salmonella enterica spp. enterica serovar Enteritidis, Listeria monocytogenes, and many others.

- In addition to the H5N1 avian influenza virus, it prevents the spread of SALMONELLA and various other pathogens.

- Elevate your operations with AGROfogg®, the ultimate solution that seamlessly combines disinfection, humidification, and dust reduction for a safer and more efficient environment.

Efficient and Cost-Effective

Our dry mist technology stands as a highly effective solution against invisible threats.

What We Provide

Choosing the right solution to maintain high standards of cleanliness in food production and storage areas can be complex, but with the AGROfogg® system, you can be confident that you have the most advanced and effective technology on the market. The system is designed to help improve air quality and eliminate air from unwanted pathogens.

Whole-space cleaning

Automated

Residue-free

Safe for food and people

Factors of Food Contamination

- Inadequate Hygienic Practices: Inadequate adherence to hygiene standards by employees can lead to food contamination.

- Insufficient Cleaning and Disinfection: Inadequate cleaning and disinfection of production areas, equipment, and tools can allow the growth and spread of bacteria and viruses.

- Inadequate Temperature and Humidity Control: Unfavorable temperature and humidity conditions can create an ideal environment for the growth of microorganisms.

- Contamination of Raw Materials and Water: The use of contaminated raw materials or water in production can contribute to the spread of bacteria and viruses.

- Inadequate Maintenance of Equipment and Infrastructure: Outdated or damaged equipment and infrastructure can be a source of contamination.

- Migration of Harmful Microorganisms through Ventilation Systems: Contaminated air can transmit bacteria and viruses from one part of the production facility to another.

Simple & Powerful

Your custom static disinfection project for each production section

Identification of Risk Areas

Each section is analyzed to identify areas with a high risk of contamination or spread of pathogens. Older or not entirely new buildings have many areas that are very difficult to clean and disinfect. Such production facilities or their equipment are often highly contaminated.

Installation of Static Disinfection

The system installation is conducted around the perimeter of the spaces using stainless steel pipes, and depending on the client's needs, positions for the nozzles are selected to disperse the disinfectant dry mist. Our goal is to cover the entire necessary part of the production from top to bottom

Sterile Environment

The dry mist produced from SANOSIL disinfectant disrupts the cell walls of microorganisms, ensuring their elimination in the air and on surfaces throughout the space. Escherichia coli, Candida albicans, Enterococcus faecalis, Salmonella enterica spp. enterica serovar Enteritidis and Listeria monocytogenes and more.

Humidity

Managing optimal humidity levels is also our specialty. To maintain a constant level of humidity, we use thermo-humidity sensors, which ensure minimal deviation in humidity change. HydroFogg is suitable for use in 24/7 operations as well.

Comprehensive Coverage

The dry mist technology permeates the air to all areas within the space, ensuring the cleaning of both air and surfaces. Thanks to the safe disinfectant of SANOSIL, we disinfect the air and surfaces within a matter of minutes!

Disinfection at the Level of Sterility

Static disinfection enables achieving high-quality results repeatedly during each operation. The outcome is a high standard of cleanliness and product quality. Excellent control results. Protection of the company's good name.